Expertise, Spotlights

Spotlight: A cornflower soap is created

Oct

Savondine soaps are carefully handmade in Switzerland. This wonderful series of pictures gives an insight into the soap-making process and shows how Savondine's wonderful cornflower soap is created.

Savondine's natural soaps are made from native plant oils. This soap contains valuable oils such as the finest babassu oil, shea butter and olive oil.

The fats and oils are melted at a low temperature until clear. Everything is then allowed to cool back down to room temperature.

As yellow clay conjures up subtle nuances in the soap, it is used to colour part of the soap glue.

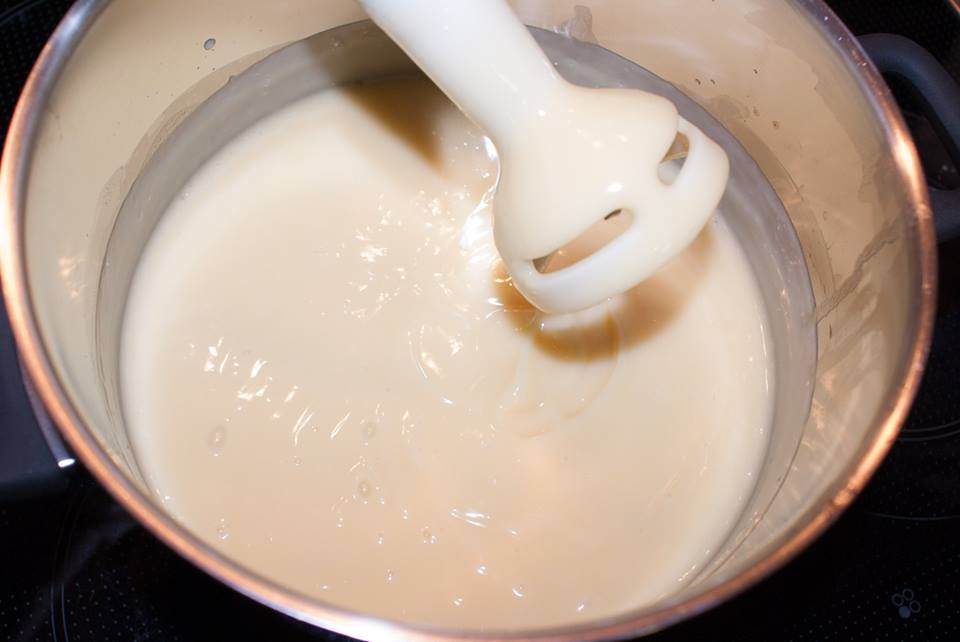

To create soap from the mixture, sodium hydroxide solution, which has also cooled to room temperature, is poured into the shiny golden oils.

This picture clearly shows the change. The hand blender can do in a few minutes what can take several hours by hand.

The finest essential citronella oil is added to the soap glue to give the soap a fresh, tangy fragrance.

You can already see the thicker soap glue. For the cornflower soap, the glue is stirred until it "draws". This is achieved when the surface retains its structure and no longer melts when stirred with a spoon.

The soap glue is now poured into the moulds. First comes the uncoloured soap paste and then the paste that has been mixed with yellow clay to create a nice, warm colour.

The soap mixture is filled into the mould, given a nice "topping" and then covered with precious cornflower blossoms. Now the soap is ready to be "put to sleep" for 36 hours. It is then moulded and matures for a further eight weeks until it is ready for sale as a fine Savondine cornflower soap can be sent to lovers of fine craftsmanship and soap art.